Custom Precision Spacers and Shims

Optimize Your Prototyping and Testing with Custom Precision Parts

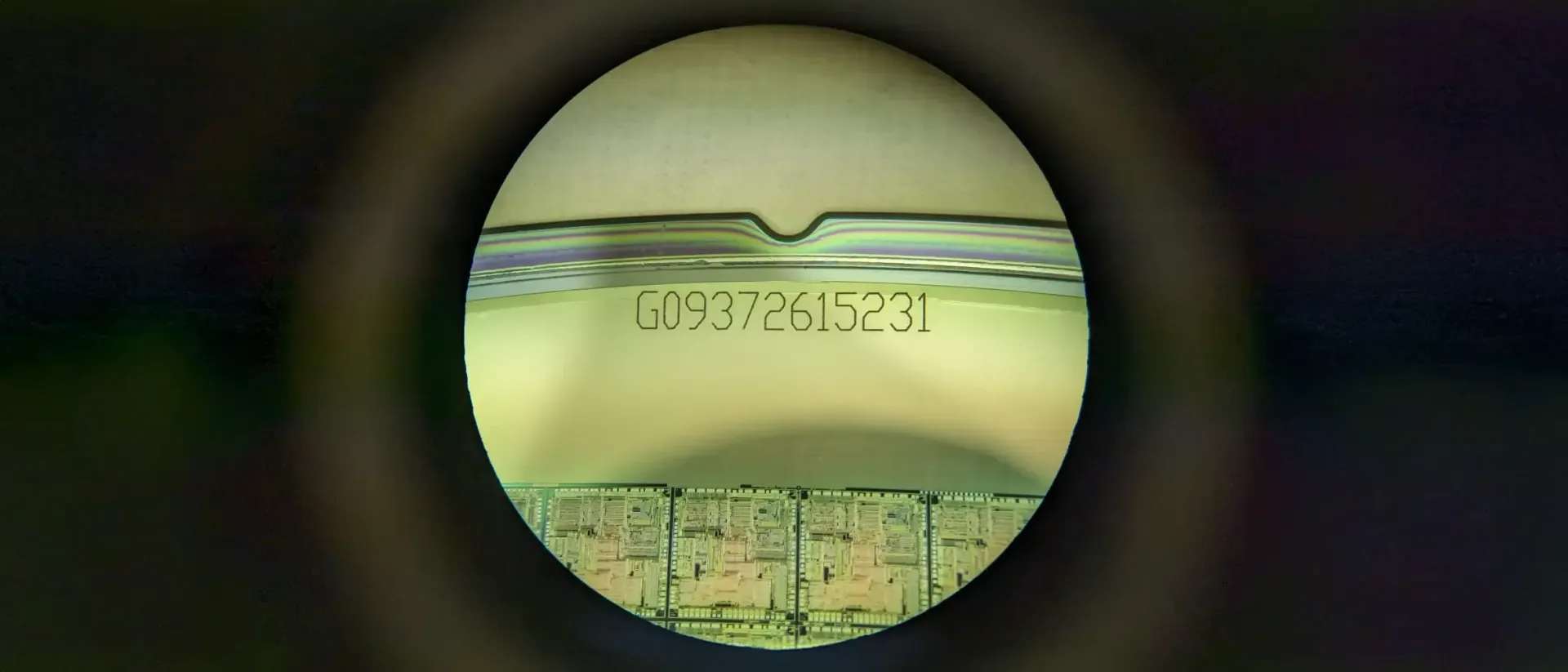

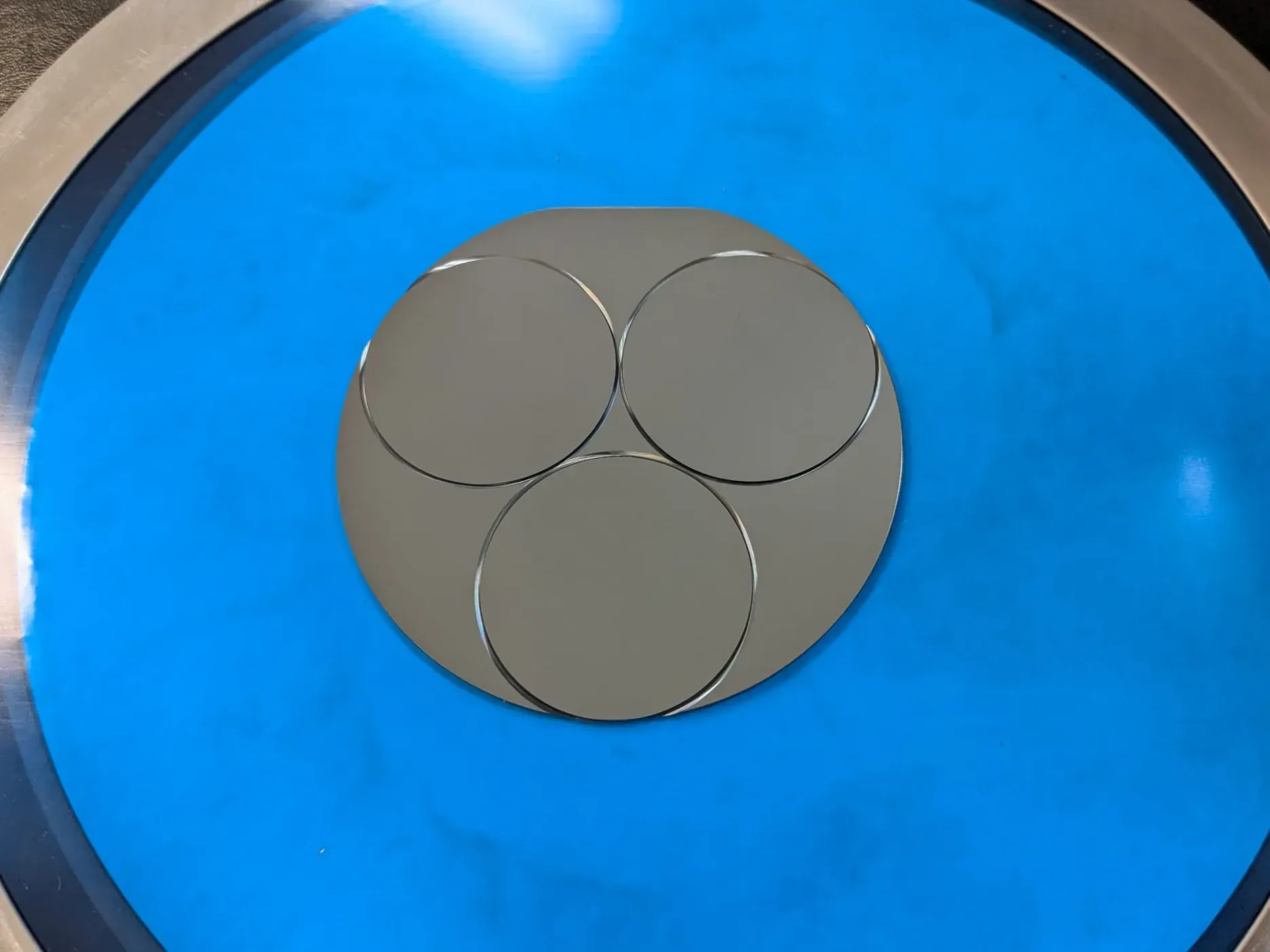

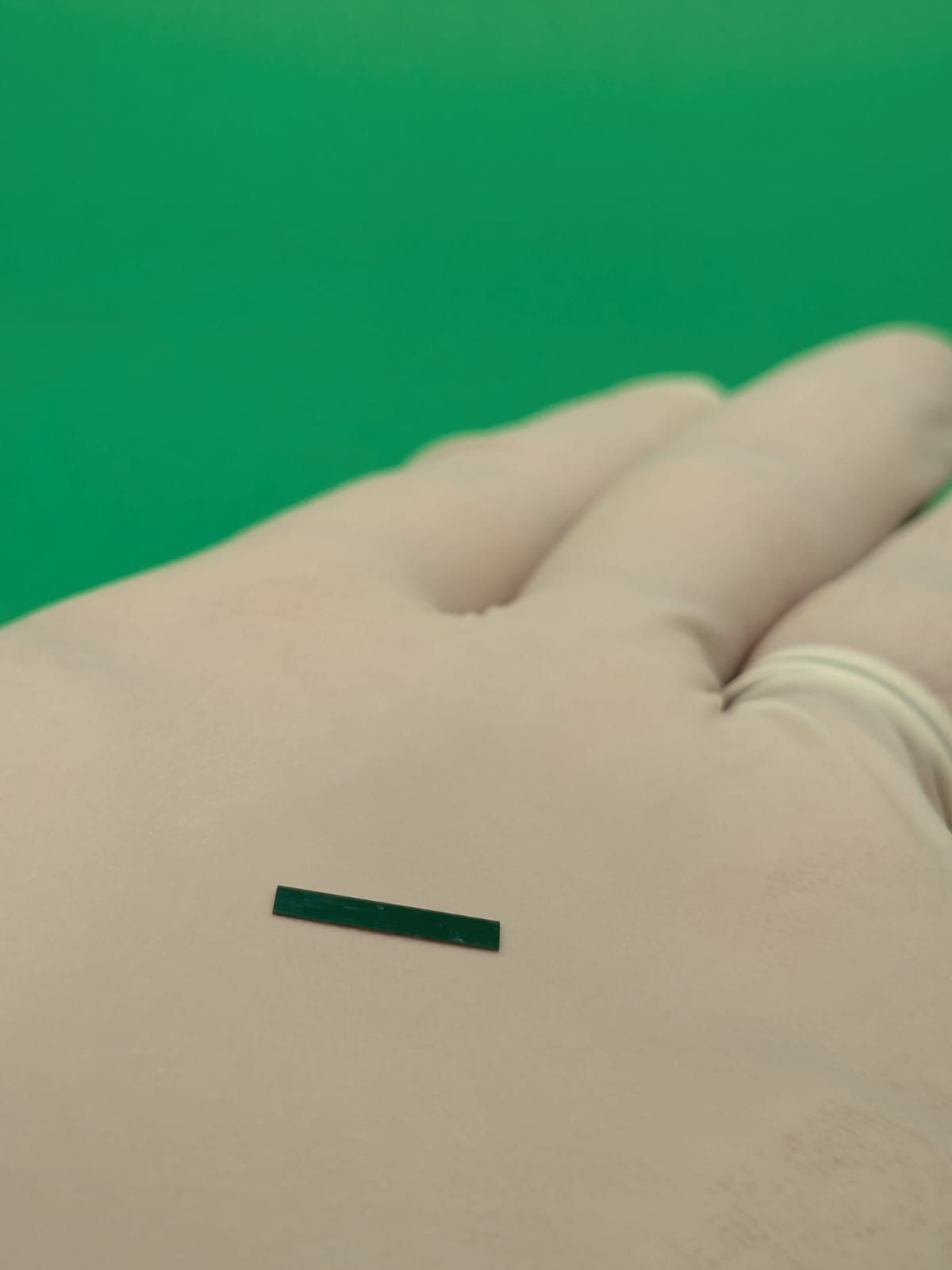

APD offers turnkey custom chips designed to serve as shims, spacers, and coupons for various applications, including prototyping and testing. Our ready-to-use parts can be laser marked with serial numbers, part numbers, or bar codes, providing a complete solution that saves you time, money, and hassle.

What We Provide

At APD, we specialize in creating custom precision spacers and shims tailored to your specific requirements. Our offerings include:

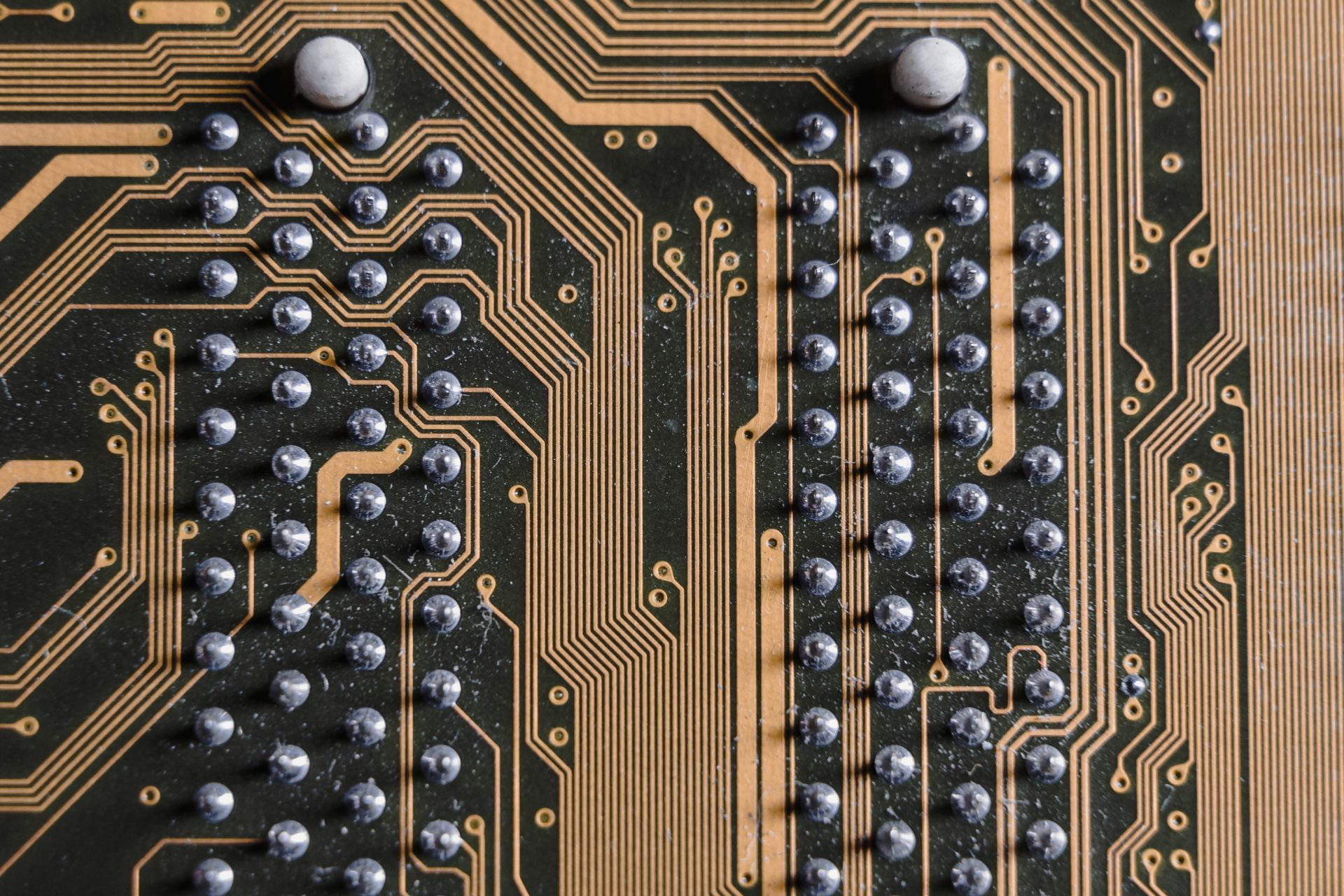

Materials: We work with non-metallic materials such as silicon, glass, and sapphire.

Dimensions: Precisely crafted to your X, Y, and Z measurements.

Optional Customizations: Choose from custom coatings or specialized laser markings for easy identification.

These components are ideal for a range of industries, including semiconductor manufacturing, aerospace, and medical devices, where precision and reliability are paramount.

The Traditional DIY Approach

Typically, creating custom shims and spacers involves a complex, multi-step process:

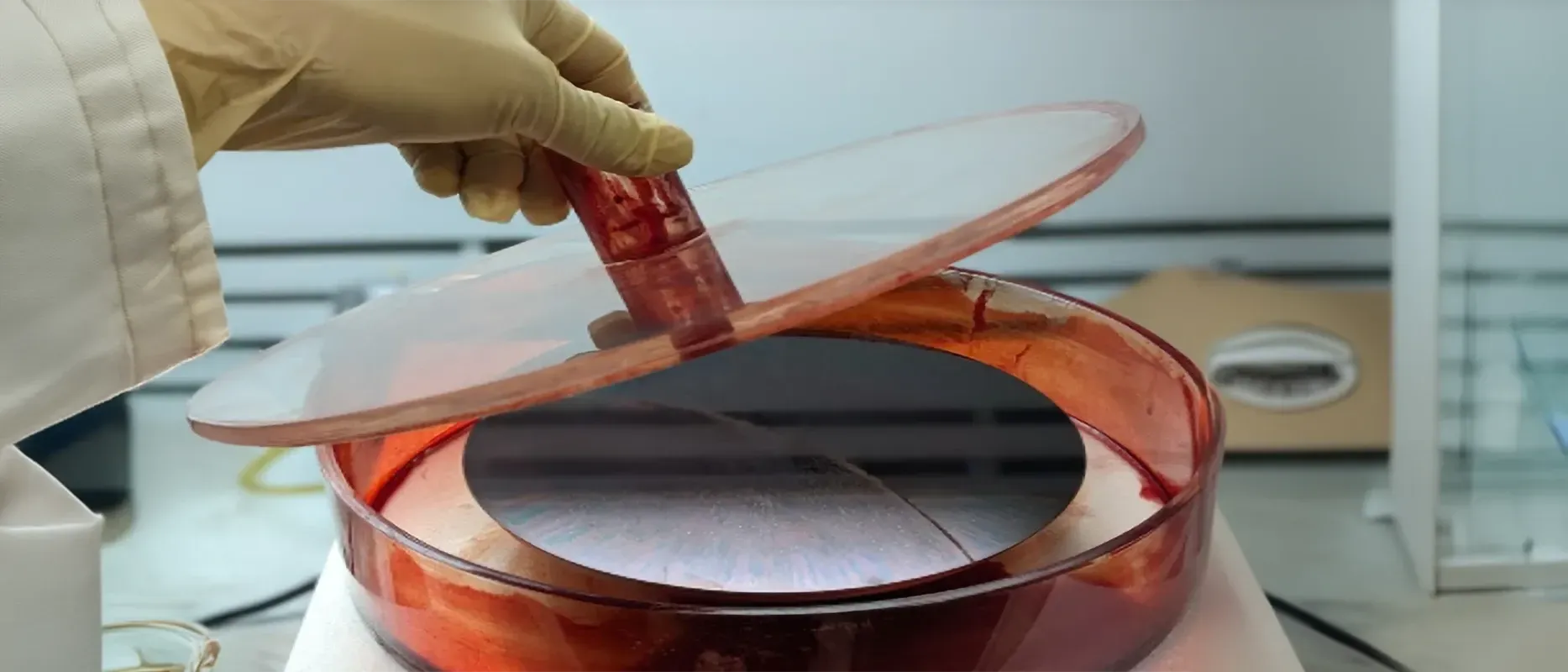

- Source a wafer from a wafer house.

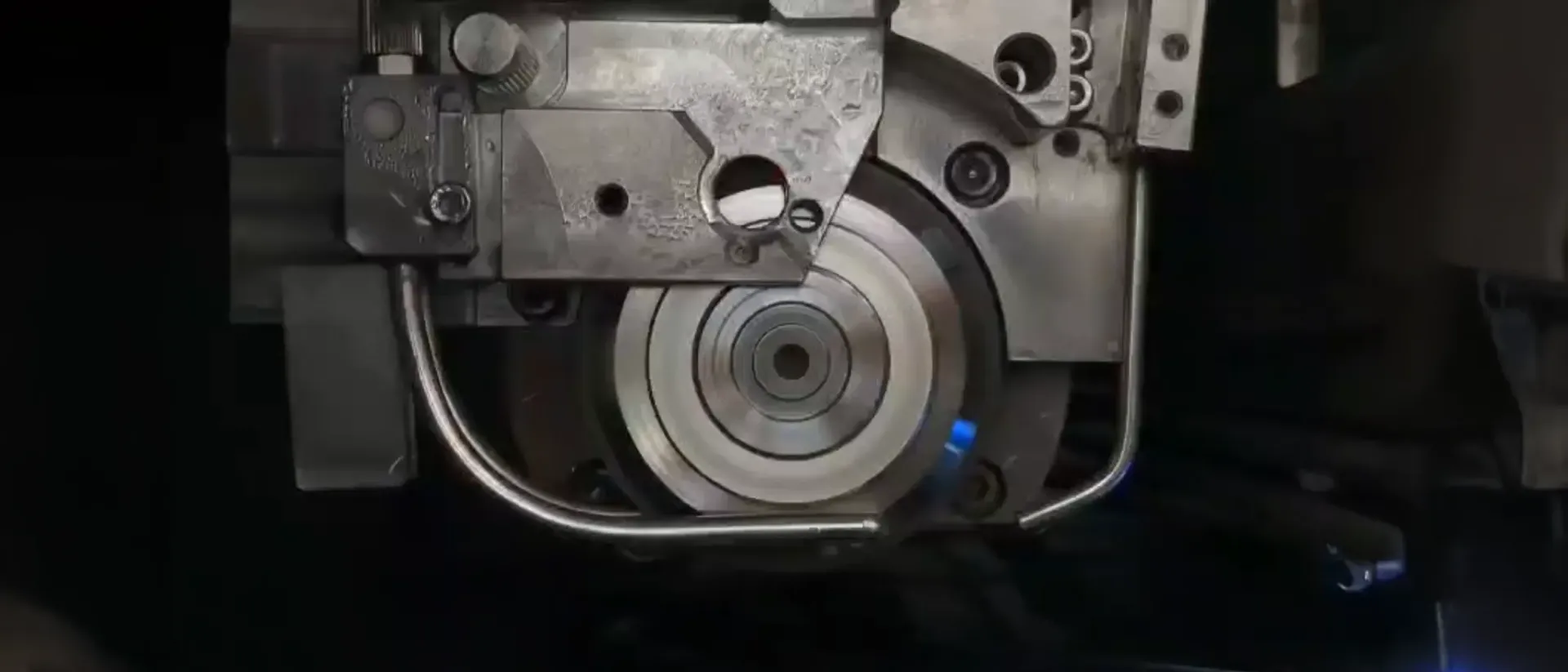

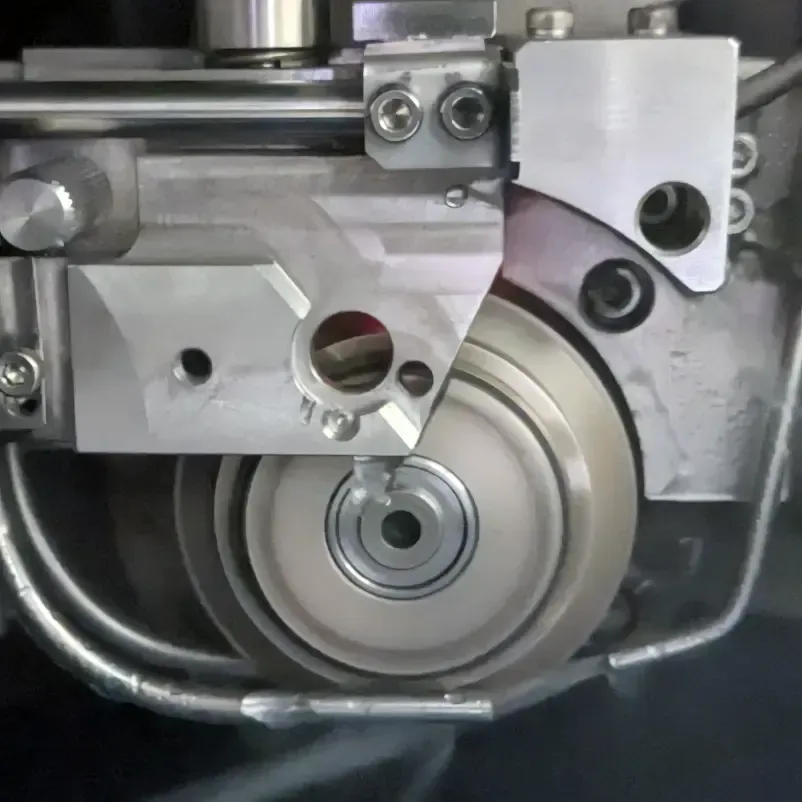

- Backgrind the wafer to the desired thickness.

- Polish the wafer if required.

- Apply the oxide layer or other coatings.

- Arrange for dicing services to cut the wafer.

- Add serial numbers or other identifiers.

- Package the parts in waffle packs, gel-paks, or on tape and ring.

This approach not only consumes valuable time but also increases the risk of errors at each stage.

The APD Advantage

Why go through the hassle of coordinating multiple vendors when APD can handle the entire process for you? Our end-to-end service ensures that you receive high-quality, custom-made spacers and shims that meet your exact specifications, delivered quickly and efficiently.

If you're interested in our custom precision spacers and shims service, contact us at

+1(408)539-9880,

sales@wafer-dicing.com, or visit our

Request a Quote page to get started. Let us help you achieve precision and efficiency in your semiconductor manufacturing processes.